After the use of considerable time, the force surface into a larger rounded corners, you can remove the knife blade splint to turn the blade 180 degrees, can continue to use after fastening.

Product warranty requirements within six months from the date of shipment of the machine manufacturing quality problems that can not be used (not including wearing parts blade, fixed knife) factory is responsible for repair. But the motor load and burned or material within the metal, stones and other debris and damage to mechanical parts, the repair costs by the user themselves.

The overall components of the machine

SMW-500 a milling machine

Y200L12 (37KW) one motor

Model 9-19.4 # with a motor 4KW of a draft fan

Model ZGF with a motor 0.75KW off a fan

Cyclone collector (including duct) a set.

Overview of vertical multi - purpose plastic milling machine

The machine is developed by the factory's latest mill, its characteristics are as follows:

Increased dust collection device, effectively reduces the dust pollution.

Off the fan to reduce the labor intensity of the workers.

Main door can be opened, easy maintenance and replacement of the tool.

The use of feng shui double cold, better reduce the body's working temperature, the grinding of the material is not easy to change color, but also conducive to the heat-sensitive plastic grinding, can be part of PE, EVA, SBS, ABS grinding.

working principle

1. The working part of the machine for the cutterhead, high-speed particles in the impact of the fixed knife and tooth pieces after the quilt crushed by the suction fan, while the larger particles continue to impact, crushed out, thus reducing the load on the cutter, Efficiency, but also make the powder to be uniform cooling.

2. Low temperature is the main advantage of the machine, according to the heat equivalent: after 8 hours per kilogram of work converted to heat, the machine for external ventilation, air volume of 50 cubic meters / kilowatt, by the import and export wind temperature difference, Part of the heat. A small amount of heat is cooled by water.

use

The factory absorbs foreign advanced technology research and development of a series of milling machines for high-density PE, EVA, SBS, ABS and other plastic after a successful trial. Therefore, this equipment is the plastic products factory to reduce costs, to solve the accumulation of waste the best equipment.

Technical Parameters

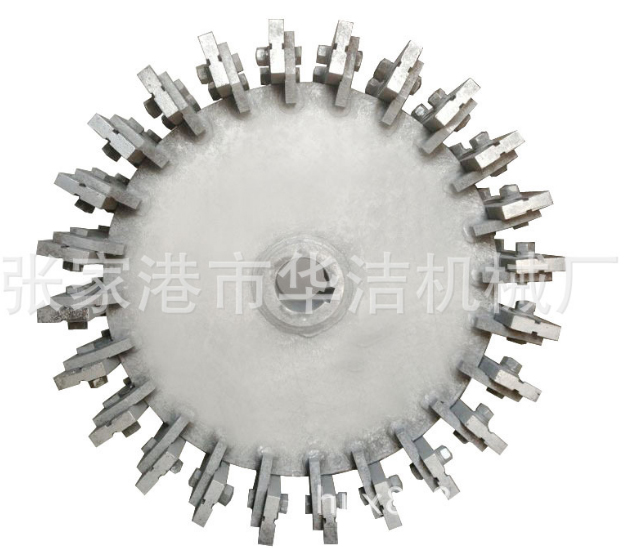

1. Number of cutter: 1, outer diameter: 491mm

2. Fixed knife: 1 pay

3. Blade: 24 pieces

4. Main motor speed: 2950r / min

5. Main motor power: 37KW

6. Fan: Model 9-19, with motor 4KW

7. Off fan: Model ZGF, equipped with motor 0.75KW

8. Overall dimensions: 1750 * 1000 * 4200 (H)

9. Machine weight: 1500KG

Safety Precautions:

Familiar with the contents of the instructions and the role of electrical buttons, the direction of rotation of the host must meet the direction of the arrow marked on the belt cover.

Start the fan should be started before (attention to steering), to be operating normally, start the host to the normal speed, the start feeding.

Production began, the feed port valve to open as long as the material can be employed to book, and then slowly open the door cover, depending on the material into the machine, the machine load conditions, generally about 68A is appropriate, because the electronic control panel ammeter Measured 37KW +4 KW and line, so the total current value is 70A, in normal operation, the current should be between 65-70A, swing.

Material requirements: the maximum diameter of pellets shall not exceed 15mm Avoid metal, stones and other strayed into the machine, so as not to aggravate wear and damage to the blade, the knife.

If there is abnormal sound during operation, immediately shut down, open the door cover inspection, can only be excluded after the production.

maintenance

1 Open the door regularly and check that the nuts, nuts and nuts of the blades are loose and tighten if loosened.

2 Lubrication: The host bearing uses lithium-based disulfide molybdenum (MoS2) grease

3 Fans and ducts shall be inspected monthly for their blades and inner walls of the pipes and to remove dust from their compaction.